MEAG Power, Participant & Public Power News

Fall/Winter 2022-2023

Vogtle News

Major Milestone Reached as Plant Vogtle Unit 3 Fuel Loaded; Startup Testing Has Begun

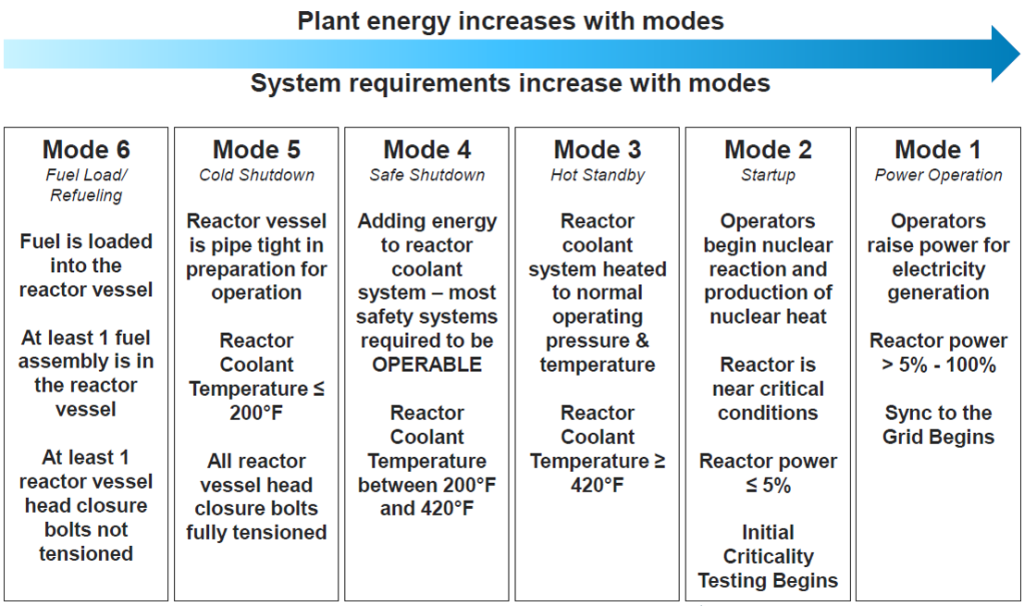

Startup testing for commercial operation is proceeding through a number of progressive levels, called modes, leading to Unit 3 entering commercial operation, slated for April 2023.

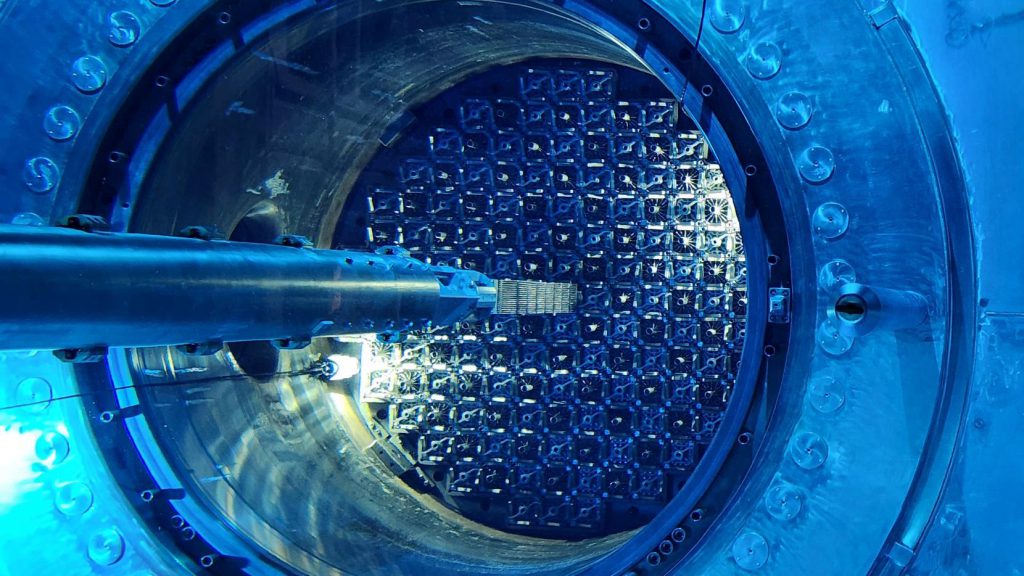

On October 14, fuel load into the Vogtle Unit 3 reactor core began at Plant Vogtle. The fuel load process marked a historic and pivotal milestone toward startup and commercial operation of Unit 3.

During fuel load, nuclear technicians and operators from Westinghouse and Southern Nuclear safely transferred 157 fuel assemblies one-by-one from the Unit 3 spent fuel pool to the Unit 3 reactor core over the span of three days.

Startup testing then began. It is designed to demonstrate the integrated operation of the primary coolant system and steam supply system at design temperature and pressure with fuel inside the reactor. Operators will also bring the plant from cold shutdown to initial criticality, synchronize the unit to the electric grid and systematically raise power to 100%.

This testing process leading to commercial operation takes a number of weeks. Vogtle Unit 3 is projected to enter service by April.

Testing must progress through a series of “modes,” from Mode 6 to Mode 1. The modes are designed to progressively test operational and safety systems with increasing temperature and pressure, in Mode 2 reaching the point of “initial criticality” — or a nuclear reaction in the core. At this point, Unit 3 will have reached startup. Finally, in Mode 1, operators will raise the unit’s power to 5%, and synchronize the unit to the grid. The unit power output will be raised to various levels over several weeks, ultimately reaching 100% reactor output before beginning commercial operation.

Testing had reached Mode 3 by the time of publication of this issue.

Unit 4 Progress Update

In early December, Unit 4 completed cold hydro testing, which is required to support the last major test remaining for Unit 4, hot functional testing. Hot functional testing is projected to commence by the end of the first quarter of 2023. Unit 4 is slated to enter commercial operation by the end of the 4th quarter of 2023 or in the 1st quarter of 2024.

Cold hydro testing on Unit 4 confirmed the reactor’s coolant system functions as designed and verified the welds, joints, pipes and other components of the coolant system and associated high-pressure systems do not leak when under pressure. As part of the testing, the reactor coolant system was filled with water and pressurized above-normal operating conditions, then lowered to normal design pressure while comprehensive inspections were conducted to verify the systems meet design standards.

Other recent milestones for Vogtle Unit 4 include:

- Closed vessel testing (CVT) – Completed in early November, this testing process verified that the pipes and valves in the Unit 4 reactor coolant system are installed as designed and helps ensure safety systems function properly. To carry out CVT on the plant’s passive safety systems, workers installed the reactor vessel head as well as the lower and upper reactor internals and flow restrictors which will be used during hot functional testing to mimic flow through the reactor core.

- Rotation of turbine on turning gear – Also in November, the Unit 4 Turbine was rotated on its turning gear for the first time, demonstrating the turbine was assembled with quality and that integrated oil systems function as designed. The main turbine system consists of one high-pressure turbine and four low-pressure turbines. Rotating the turbines on the turning gear ties in all the oil systems and a significant number of supporting systems in the turbine island, which is a separate structure outside of the unit’s nuclear containment building. Once operational, the turbine will rotate at 1,800 revolutions per minute, propelled by steam produced by the unit’s two steam generators using heat transferred from the nuclear reactor. The turbine blades turn the generator rotor to produce electricity.

Quick Links:

Meetings & Events

-

-

Participant Dinner in conjunction with GMA Cities United

Jan. 22, 6 p.m. - 9 p.m. -- Commerce Club, Atlanta

See details

Other Resources

Current is published by MEAG Power

1470 Riveredge Parkway, N.W., Atlanta, Georgia 30328 | www.meagpower.org | (800) 333-MEAG